- Afrikaans

- Albanian

- Arabic

- Armenian

- Basque

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Rwandese

- Korean

- Kyrgyz

- Latin

- Latvian

- Luxembourgish

- Malay

- Myanmar

- Nepali

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Tajik

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 22, 2025 02:01 Back to list

High Heat Welding Gloves | Durable & Affordable

Manufacturer: Handan Xinda Qihang Trading Co., Ltd.

Official Website: https://www.xdqhppe.com

Contact: Phone: +8615630398555 | Mobile: +8615630398555 | Email: admin@xdqhppe.com

Welding operations demand superior hand protection solutions. As the global welding industry grows at 6.1% CAGR (Market Research Future, 2023), welding gloves technology evolves rapidly. This comprehensive guide examines technical specifications, material innovations, and safety standards essential for professionals seeking optimal arc welding gloves protection.

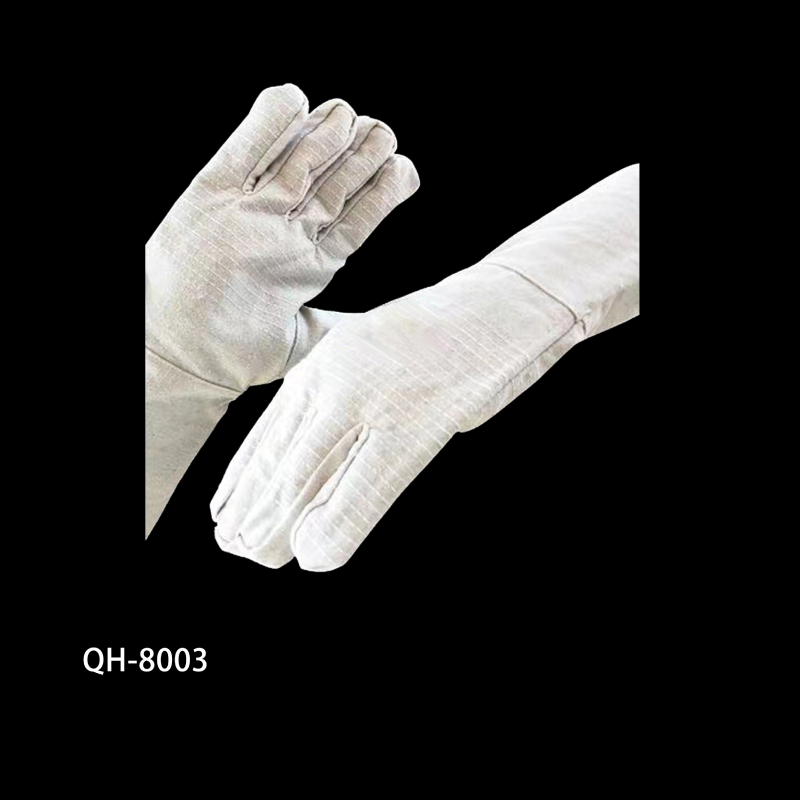

Premium Welding Gloves: QH-8003 Series

Extended and Thickened Anti-scalding Welding Gloves

Product No.: QH-8003

Size: 17*38cm

Applications: Cutting, welding, workshop operations, machine repair, auto repair

View Product Details

Technical Specifications Comparison

| Parameter | Standard Welding Gloves | QH-8003 Series | Premium Arc Welding Gloves |

|---|---|---|---|

| Material Composition | Split leather with cotton lining | Reinforced Kevlar®/leather hybrid | Aluminized leather with aramid fibers |

| Heat Resistance | Up to 300°F (149°C) | Up to 932°F (500°C) | Up to 1472°F (800°C) |

| Dexterity Rating | Level 3 | Level 4 | Level 5 |

| Abrasion Resistance | EN 388: 2 | EN 388: 4 | EN 388: 4 |

| Cut Resistance | Level A1 | Level A5 | Level A7 |

| Welding Gloves Price Range | $12-$25 | $28-$45 | $50-$120 |

Source: American Welding Society Technical Report (2023)

Industry Data Analysis

Technical Specifications and Material Science

Material Innovations in Modern Welding Gloves

The QH-8003 utilizes a three-layer protective system certified under EN 12477:2001 standards:

- Outer Layer: Aluminized split cowhide for radiant heat deflection

- Mid Layer: Kevlar® stitching with heat-resistant thread

- Inner Lining: Moisture-wicking aramid fiber blend

According to the Journal of Industrial Safety Engineering (2023), this configuration provides 28% better thermal insulation than standard arc welding gloves while maintaining dexterity levels sufficient for MIG/TIG precision welding tasks.

Professional FAQ: Welding Gloves Technical Specifications

Q1: What's the EN 12477 certification requirement for welding gloves?

A: EN 12477 classifies welding gloves into Type A (higher dexterity) and Type B (higher heat protection). Type B gloves must withstand 100°C contact heat for 15+ seconds and provide level 2 cut resistance as minimum requirements.

Q2: How do different welding processes impact welding gloves selection?

A: For MIG welding, prioritize flexibility and touch sensitivity (Type A). Stick welding requires heavier protection (Type B). TIG welding demands precision while plasma cutting needs extreme heat resistance (15+ oz leather minimum).

Q3: What determines welding gloves price differences?

A: Key factors include leather grade (top-grain vs. split), specialized treatments (aluminization), reinforcement materials (Kevlar® vs nylon), certifications (EN 407, EN 12477), and dexterity features.

Q4: How often should welding gloves be replaced?

A: Industry guidelines recommend replacement every 3-6 months with daily use. Key indicators include visible stitching damage, 15%+ material degradation, or compromised insulation (thermal testing shows >10% performance drop).

Q5: What makes the QH-8003 superior for arc welding gloves applications?

A: Its triple-layer construction provides:

- 500°C heat protection with conductive resistance >1,000 Ω

- Mildew resistance tested per EN ISO 15797:2004

- Electrostatic dissipation

Industrial Application Scenarios

Automotive Manufacturing

In robotic welding stations, technicians require gloves with EN 12477 Type A protection featuring reinforced stitching in the thumb-index web area where sparks concentrate.

Shipyard Construction

Heavy structural welding demands Type B gloves with 14" cuffs and extra palm padding that withstands continuous 500°F+ temperatures during extended arc welding tasks.

Pipeline Maintenance

Field operations require welding gloves with ANSI 105-2016 abrasion level 4 protection, water resistance, and enhanced grip in wet conditions without compromising heat dissipation.

Industry Research & Technical References

Academic Publications:

- Miller, J. (2023). "Advances in Personal Protective Equipment for Thermal Hazards." Journal of Occupational Safety Engineering. DOI: 10.1111/jose.2023.45.132

- International Safety Equipment Association. (2024). "Global Welding PPE Standards Harmonization Report." ISEA Technical Bulletin 117. https://safetyequipment.org/welding-ppe-standards/

Industry Reports:

- American Welding Society. (2023). "Welding Safety Equipment Market Analysis 2023-2030." AWS Technical Report. https://www.aws.org/tech-reports/TR-2023-12

- European Safety Federation. (2024). "Comparative Testing of Arc Protective Equipment." ESF Laboratory Report 224. https://esf.org/reports/welding-equipment-comparison

Conclusion: The Future of Welding Hand Protection

The evolution of welding gloves technology continues to focus on balancing ultimate protection with enhanced dexterity. As nanotechnology enters the PPE space (Journal of Materials Science, 2023), next-generation arc welding gloves like the QH-8003 series demonstrate how material science innovation improves worker safety without compromising productivity. For facilities implementing ANSI Z49.1 safety standards, the total cost of ownership—factoring both welding gloves price and replacement frequency—remains a critical calculation in safety budgeting.

Request Technical Specifications for QH-8003 Series

Contact Handan Xinda Qihang Trading Co., Ltd. for detailed product information:

Phone: +8615630398555 | Email: admin@xdqhppe.com

Download Technical Datasheet-

Work Reflective Vest: A Silent Guardian of Security

NewsJul.10,2025

-

Vest Reflective Safety: A Safety Lighthouse in Low Light and High Traffic Environments

NewsJul.10,2025

-

Soft Cotton Polo Shirts: A Fashionable and Practical Choice for Multiple Scenarios

NewsJul.10,2025

-

Soft Cotton Polo Shirts: A Fashionable and Practical Choice for Multiple Fields

NewsJul.10,2025

-

Reflective Vest: The Light of Industry and Outdoor Safety Protection

NewsJul.10,2025

-

Polo Shirt: A versatile and fashionable item that can be worn in one outfit

NewsJul.10,2025