- Afrikaans

- Albanian

- Arabic

- Armenian

- Basque

- Belarusian

- Bengali

- Bulgarian

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Finnish

- French

- German

- Greek

- Hebrew

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- kazakh

- Rwandese

- Korean

- Kyrgyz

- Latin

- Latvian

- Luxembourgish

- Malay

- Myanmar

- Nepali

- Persian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Slovak

- Spanish

- Swedish

- Tagalog

- Tajik

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Sep . 04, 2024 16:10 Back to list

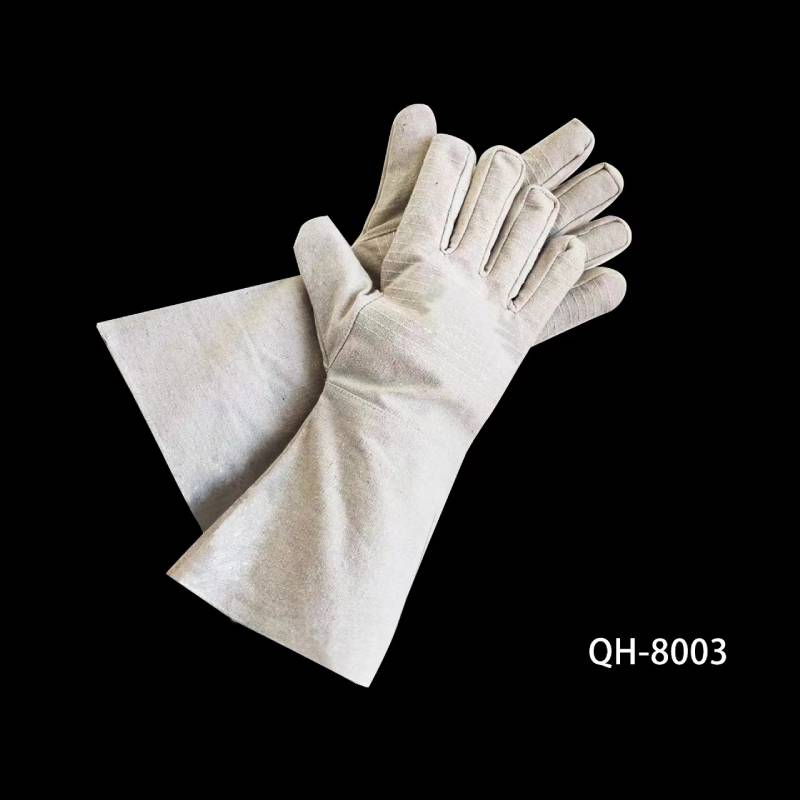

Hot Oil Gloves - High-Quality Heat Resistant Gloves

The Importance of Hot Oil Gloves in Industrial Safety

In industries involving high-temperature processes, such as food production, oil refining, and metal fabrication, worker safety is paramount. One of the essential pieces of personal protective equipment (PPE) that ensures safety in these environments is hot oil gloves. Designed specifically to protect wearers from burns and injuries associated with handling hot materials, these gloves play a critical role in preventing accidents and enhancing workplace safety.

Hot oil gloves are crafted from specialized materials that offer excellent heat resistance. Common materials include aramid fibers, neoprene, and leather, each chosen for their unique properties that provide insulation and durability. In situations where workers are required to handle hot oil, molten metal, or any heated objects, these gloves serve not only to insulate but also to provide a reliable grip. This is crucial as handling slippery substances can lead to accidents, making the combination of heat resistance and grip essential for worker safety.

The effectiveness of hot oil gloves is contingent on their design and construction. Quality gloves typically feature reinforced seams and a long cuff to protect the wrists, which are often exposed to heat when handling large containers or equipment. Additionally, many gloves offer flexibility, allowing workers to maintain dexterity while manipulating tools or machinery. This balance between protection and functionality helps workers perform their tasks without compromising safety.

hot oil gloves

In industries where burns can occur frequently, the adoption of hot oil gloves is often mandated by safety regulations

. Organizations are increasingly aware of the implications of inadequate protective measures, not just in terms of employee health, but also regarding productivity and legal liabilities. An injury due to negligence in safety protocols can lead to increased medical costs, lost labor hours, and damage to company reputation. As such, the investment in high-quality PPE like hot oil gloves is not only a legal requirement but also a wise business decision.Training employees on the proper use of hot oil gloves is equally important. Workers must be aware of when to wear gloves, how to select the right type for the task at hand, and the limitations of their protective gear. For instance, while gloves may be resistant to high temperatures, they can still be compromised by prolonged exposure to extreme heat or sharp objects. Regular training and safety drills can help reinforce this knowledge, ensuring that safety becomes a part of the workplace culture.

Moreover, as technology advances, manufacturers are continuously improving the designs and materials used in hot oil gloves. New innovations include gloves that offer chemical resistance alongside heat protection, catering to industries where oil and hazardous chemicals are often handled together. Additionally, the integration of breathable materials enhances comfort during prolonged use, allowing workers to stay focused on their tasks without the distraction of discomfort.

In conclusion, hot oil gloves are an indispensable element of workplace safety in high-temperature environments. By providing protection against burns and enhancing grip, they help prevent accidents and ensure that workers can perform their tasks safely and efficiently. As businesses continue to prioritize the health and safety of their employees, investing in quality hot oil gloves and ensuring proper training will remain a vital aspect of industrial safety protocols.

-

Work Reflective Vest: A Silent Guardian of Security

NewsJul.10,2025

-

Vest Reflective Safety: A Safety Lighthouse in Low Light and High Traffic Environments

NewsJul.10,2025

-

Soft Cotton Polo Shirts: A Fashionable and Practical Choice for Multiple Scenarios

NewsJul.10,2025

-

Soft Cotton Polo Shirts: A Fashionable and Practical Choice for Multiple Fields

NewsJul.10,2025

-

Reflective Vest: The Light of Industry and Outdoor Safety Protection

NewsJul.10,2025

-

Polo Shirt: A versatile and fashionable item that can be worn in one outfit

NewsJul.10,2025